Blog

The Role of MBBR Technology in Energy Savings

Energy consumption is one of the largest operational costs in wastewater treatment plants. In biological treatment systems, aeration alone can account for 50–70% of total energy usage. As energy prices continue to rise and sustainability targets become stricter, treatment plants must focus not only on meeting discharge standards but also on optimizing energy efficiency.

This is where MBBR (Moving Bed Biofilm Reactor) technology plays a critical role.

Why Energy Efficiency Matters in Wastewater Treatment

Wastewater treatment facilities face three major pressures:

Increasing energy costs

Stricter discharge regulations

Carbon footprint reduction targets

Traditional activated sludge systems often require large tank volumes, high sludge recirculation rates, and continuous high aeration intensity. These factors significantly increase power consumption.

MBBR technology offers a smarter biological design approach that directly impacts energy performance.

How MBBR Technology Reduces Energy Consumption

1. Higher Biomass Concentration in Smaller Volumes

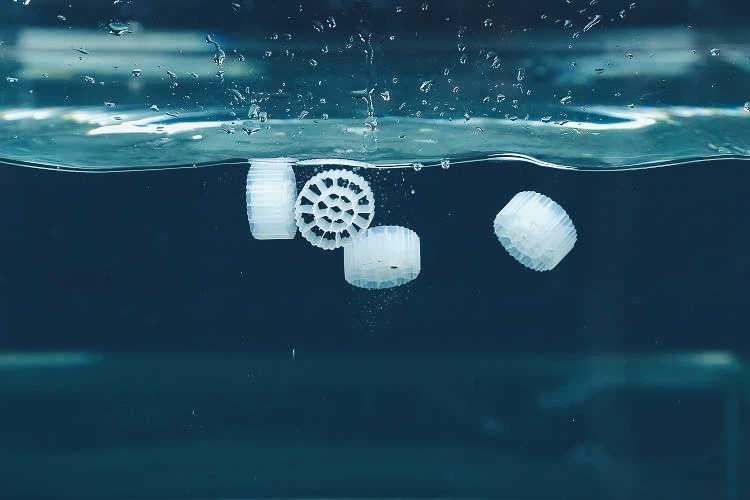

MBBR systems use biofilm carriers with high specific surface area. These carriers allow microorganisms to grow in attached biofilm form rather than remaining suspended in mixed liquor.

Result:

Higher biomass concentration

Increased biological reaction rates

Smaller reactor volume requirements

Smaller tanks mean lower aeration demand and reduced mixing energy.

2. Reduced Sludge Recirculation

Unlike conventional activated sludge systems, MBBR does not require return activated sludge (RAS) for biomass retention.

Energy impact:

No RAS pumps

Lower hydraulic load

Reduced pumping energy

This alone can significantly cut total plant electricity consumption.

3. Optimized Aeration Efficiency

In MBBR systems, aeration serves two purposes:

Oxygen transfer

Carrier movement and mixing

Because biomass is attached to carriers:

There is no need to maintain high MLSS concentrations

Oxygen transfer efficiency can be better controlled

Aeration intensity can be optimized based on process demand

This leads to lower blower capacity requirements and reduced operational hours.

4. Stable Process Performance = Less Energy Waste

MBBR systems are highly resilient to shock loads and hydraulic fluctuations.

Stable biological activity means:

Fewer process upsets

Less emergency aeration

Reduced need for corrective operational adjustments

Stability directly translates to energy savings over time.

5. Retrofit Advantage

One of the biggest advantages of MBBR technology is its ability to upgrade existing plants without constructing new tanks.

Instead of building additional aeration basins, facilities can:

Install MBBR bio media into existing tanks

Increase treatment capacity

Improve nitrification performance

All without significantly increasing energy demand.

Energy Savings in Nitrification Applications

Nitrification is one of the most energy-intensive biological processes in wastewater treatment.

MBBR systems allow:

High nitrifying biomass retention

Improved oxygen utilization

Lower sludge age dependency

This enables more efficient ammonia removal with optimized aeration control.

Environmental and Economic Impact

Energy savings from MBBR systems contribute to:

Lower operational costs

Reduced carbon emissions

Smaller plant footprint

Sustainable wastewater management

When designed correctly, MBBR technology provides both technical performance and long-term economic advantage.

Why Media Quality Matters

Energy efficiency is not only about the process design but also about the quality of bio media used.

Key parameters that directly influence energy performance:

Effective specific surface area

Proper density (close to water density)

Optimized geometry for oxygen transfer

Mechanical durability

Poor-quality carriers can increase aeration demand and reduce biological efficiency, eliminating potential energy savings.

Conclusion

MBBR technology is not just a biological treatment method — it is a strategic solution for energy optimization in modern wastewater treatment plants.

By:

Increasing biomass efficiency

Reducing pumping requirements

Optimizing aeration demand

Enhancing process stability

MBBR systems help facilities achieve both environmental compliance and energy sustainability goals.

Contact Us

At Enke Group, we manufacture and supply high-performance MBBR bio media (Oxy-Film Carrier) designed for maximum surface efficiency and optimized biological performance.

If you are planning:

A new wastewater treatment plant

A capacity upgrade

An energy optimization retrofit

Our technical team is ready to support your project.

📩 Contact us today to discuss how MBBR technology can improve your plant’s energy efficiency.

🌐 info@enkegroup.com

+90 224 251 62 62